-

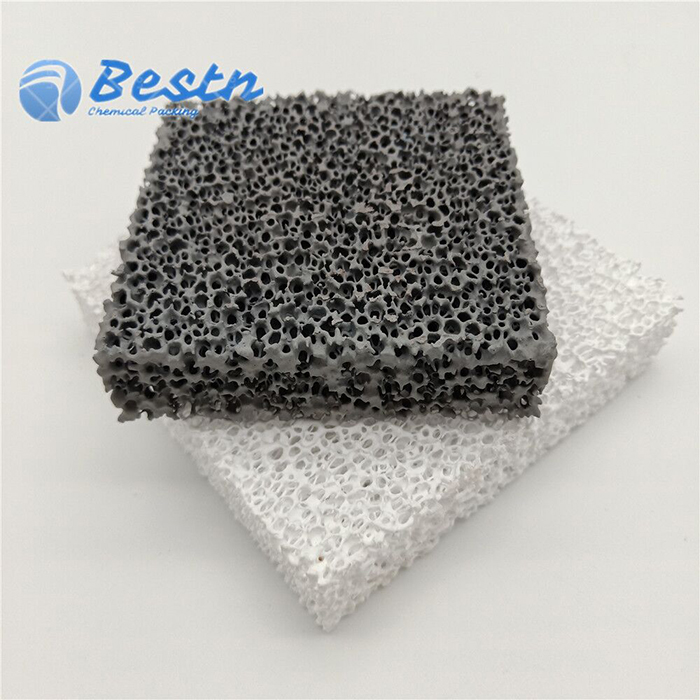

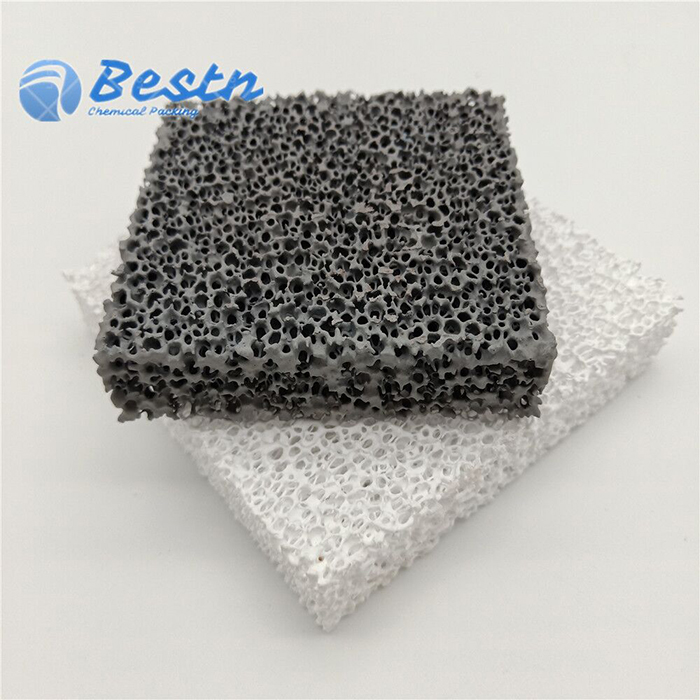

I-SIC/Silicon carbide Isihlungi se-Ceramic Foam sokuhlunga kwensimbi okuncibilikisiwe okungeyona i-ferro alloy

Izihlungi ze-Silicon Carbide Ceramic Foam ikakhulukazi zokuhlunga insimbi ekhonjiwe kanye nama-alloys angeyona ayoni.Ngokumelana kwabo okuhle kakhulu nokuhlasela nokugqwala okuvela oketshezini lwensimbi encibilikisiwe, bangasusa ngokuphumelelayo okufakiwe, banciphise igesi evalelekile ensimbi ewuketshezi futhi banikeze ukugeleza kwe-laminar, bese insimbi ehlungiwe ihlanzeke kakhulu.Insimbi ehlanzekile iphumela ekubunjweni kwekhwalithi ephezulu, izinsalela ezincane, namaphutha ambalwa okufakwa, konke okunomthelela enzuzweni esezingeni eliphansi.Izihlungi ze-SiC Ceramic Foam zitholakala kuzo zonke izilinganiso ezijwayelekile nogqinsi oluhlukile.Ama-porosities avame kakhulu yi-PPI 10, 20 kanye ne-30;ama-porosity aphezulu ayatholakala uma ecelwa.Izihlungi ezenziwe ngokwezifiso zokusika-usayizi nazo zingenzeka.

-

Isihlungi se-Alumina Ceramic Foam sokuhlunga kwe-aluminium encibilikisiwe

Isihlungi se-Alumina Foam Ceramics foundry sisetshenziselwa ikakhulukazi ukuhlunga kwe-aluminium nama-alloys e-aluminium kuma-Foundries nasezindlini zakwa-cast.Ngokumelana nokushaqeka okukhulu kokushisa okushisayo kanye nokumelana nokugqwala okuvela ku-aluminium encibilikisiwe, bangakwazi ukuqeda ngokuphumelelayo ukufakwa, ukunciphisa igesi eboshiwe futhi banikeze ukugeleza kwe-laminar, bese insimbi ehlungiwe ihlanzekile kakhulu.Insimbi ehlanzekile iphumela ekubunjweni kwekhwalithi ephezulu, izinsalela ezincane, namaphutha ambalwa okufakwa, konke okunomthelela enzuzweni esezingeni eliphansi.

-

i-zirconia yokukhipha isihlungi se-ceramic foam

Isihlungi se-ceramic se-Zirconia foam senziwe nge-zirconia yekhwalithi ephezulu futhi ehlanzekile, kusetshenziswa ifomula eyingqayizivele kanye nobuchwepheshe obuphambili bokuvikela imvelo.Inesakhiwo senethiwekhi esinezinhlangothi ezintathu ezifanayo, amandla aphezulu, ukuthungwa okuzinzile, akukho ukwehla kwe-slag, ukumelana nezinga lokushisa eliphezulu, kanye nokusebenza kahle kakhulu kwe-thermal shock resistance.Ifanele ukuhlanzwa nokuhlunga kwensimbi engagqwali, i-carbon steel, i-copper castings nezinye izixazululo ze-alloy lokushisa eliphezulu ngaphansi kwe-1700C.Ingakwazi ukuhlunga okufakiwe kwe-non-metal slag kanye nama-slags amancane njengama-micrometer, okwenza ingaphezulu lensimbi lishelele futhi linciphise ukulahlekelwa kwemishini;isihlungi singenza insimbi encibilikisiwe igcwalise imbobo ngokufanayo, futhi insimbi encibilikisiwe iba nesiyaluyalu esiphezulu ngesikhathi sokuthulula ukuthambekela, isiphithiphithi esigeleza esakhiweni sembotshana esinezinhlangothi ezintathu ekugcineni siguqulwa sibe ukugeleza kwe-laminar ezinzile kakhulu.Ukugeleza kwe-laminar kugcwalisa umgodi kangcono, okunciphisa ukugqwala komthelela wesixazululo sensimbi emgodini wokuphonsa, futhi kunciphisa kakhulu izinga lokwenqatshwa, kunciphisa izindleko zokukhiqiza, futhi kuthuthukisa ukukhiqizwa kwabasebenzi.