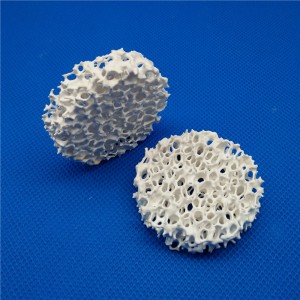

Isihlungi se-Alumina Ceramic Foam sokuhlunga kwe-aluminium encibilikisiwe

Isihlungi se-Alumina Ceramic Foam sokuhlunga kwe-aluminium encibilikisiwe

| Ubukhulu (mm) | Ubukhulu (intshi) | Izinga lokuthela (kg/s) | Umthamo wokuhlunga (ithani) |

| 178*178*50 | 7*7*2 | 0.2-0.6 | 5 |

| 228*228*50 | 9*9*2 | 0.3-1.0 | 10 |

| 305*305*50 | 12*12*2 | 0.8-2.5 | 15 |

| 381*381*50 | 15*15*2 | 2.2-4.5 | 25 |

| 430*430*50 | 17*17*2 | 3.0-5.5 | 35 |

| 508*508*50 | 20*20*2 | 4.0-6.5 | 45 |

| 585*585*50 | 23*23*2 | 5.0-8.6 | 60 |

| Okubalulekile | I-Alumina |

| Umbala | Emhlophe |

| I-Pore Density | 8-60ppi |

| I-Porosity | 80-90% |

| I-Refractoriness | ≤1200ºC |

| Ukugoba Amandla | >0.6Mpa |

| Amandla Wokucindezela | >0.8Mpa |

| Isisindo somthamo | 0.3-0.45g/cm3 |

| Ukumelana nokushaqeka okushisayo | 6 izikhathi/1100ºC |

| Isicelo | I-Aluminium, i-Aluminium alloys namanye ama-non-ferrous alloys |

1. Khipha uketshezi lwensimbi oluncibilikayo

2. Uhlelo lokungena olwenziwe lula

3. Thuthukisa isakhiwo se-metallurgical of the castings

4. Yehlisa ukungabekezelelani kokulingisa

5. Thuthukisa izinga lekhwalithi yokusakaza

6. Yehlisa ukusakaza amaphutha okufakwa kabusha kwe-oxidation yangaphakathi

7. Nciphisa amaphutha angaphezulu ngemuva kokwenza ama-castings

1.Ukwenyuka kwamanzi

Ukususwa kokufakwayo kwenza insimbi ibe uketshezi oluthe xaxa, okuholela ekugcwalisweni kwesikhunta kalula, ukwakheka okungcono kokulingwa, kanye nokusakazwa okungcono kwesigaba esincanyana.

2.Yehliswa isikhunta kanye ne-Die Wear

Ukususwa kwezinto ezifakiwe kanye nezinye izinsalela ezingezona ezensimbi ekuncibilikeni kunciphisa i-die soldering kanye nokusebenzisana kwe-mold-metal, okwehlisa isithunzi sesikhunta nempilo yesevisi.

3.Impilo Yethuluzi Elide

I-oksidi kanye ne-intermetallic inclusions idala "izindawo eziqinile" ezilimaza amathuluzi ekusebenzeni komshini nokuqeda.Ukuhlunga kunciphisa ukuguga kwamathuluzi futhi kukhulisa ukukhiqiza.

4.Okwenqatshwa Okumbalwa

I-inclusions i-nucleate porosity, idala izinyembezi ezishisayo ngesikhathi sokuqina, ibangele ukukhubazeka okulimaza ukubukeka, futhi ngokuvamile kunciphisa izakhiwo zemishini.Ezimweni eziningi, ukusikeka kokuhlunga kwenqaba kusuka ezibangweni ezinjalo kuye kuqanda.Ukuthuthukiswa kwesivuno kuze kufike ku-100% kanye nezilinganiso zokwehliswa zokunqatshwa zibe ku-0% noma eduze kwazo kuvamile.

1. Ukubunjwa kwesihlabathi

2. Ukulingisa igobolondo

3. Ukukhipha ingcindezi ephansi

4. Ukubunjwa kwesikhunta okuhlala njalo

5. Amasistimu okubamba nokudlulisa